The Architecture, Engineering, and Construction (AEC) industry is undergoing a digital revolution, and one of the most transformative innovations leading this shift is the concept of the Digital Twin. Originally rooted in manufacturing and aerospace, digital twins are now reshaping how buildings, infrastructure, and urban environments are designed, constructed, and maintained. At its core, a digital twin is a dynamic, data-driven virtual replica of a physical asset, be it a building, bridge, or entire city. For AEC professionals, understanding this technology is no longer optional, it’s essential. And this informative article is all you need if you are new to this technical word in AEC industry!

What Is a Digital Twin?

A digital twin is a virtual representation of a physical object or system, continuously updated with real-time data. Unlike static 3D models, digital twins evolve alongside their physical counterparts, reflecting changes in performance, usage, and environmental conditions.

Key components include:

- 3D models (often derived from BIM)

- Sensor data (IoT devices, environmental monitors)

- Analytics engines (AI, machine learning)

- Visualization platforms (dashboards, simulations)

- Data integration platform

- Lifecycle management tools

This convergence of design, data, and intelligence allows stakeholders to simulate scenarios, monitor performance, and optimize outcomes throughout the asset’s lifecycle.

Types of Digital Twins in the AEC Industry

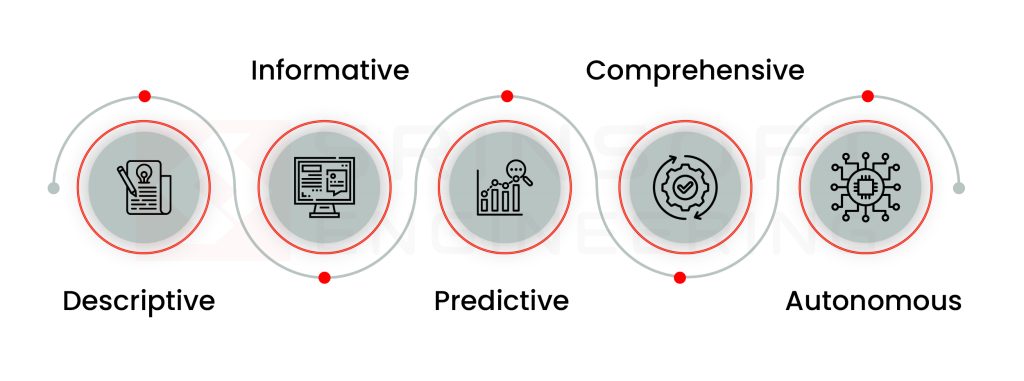

Digital twins in the AEC industry are not one-size-fits-all—they evolve in complexity and capability as organizations advance in digital maturity. From basic visual replicas to intelligent systems capable of autonomous decision-making, each type of digital twin offers increasing value across design, construction, and operations. Below is a breakdown of the five key types, aligned with progressive levels of transformation.

Level 1: Descriptive Twin

The Descriptive Twin is the foundational stage of digital twin adoption. It provides a visual replica of the physical asset, enriched with live, editable design and construction data. This includes 3D models and BIM (Building Information Modeling), offering a centralized view of geometry, materials, and spatial relationships. While static in behavior, it sets the groundwork for deeper integration and collaboration across disciplines.

Level 2: Informative Twin

The Informative Twin builds on the descriptive model by integrating sensor data and operational inputs. This twin delivers real-time insights into asset performance, environmental conditions, and usage patterns. By connecting physical systems to digital platforms, stakeholders gain visibility into how the asset behaves over time—enabling smarter monitoring and early-stage diagnostics.

Level 3: Predictive Twin

The Predictive Twin introduces analytics and contextual intelligence. It captures real-time data streams and applies algorithms to forecast potential issues—such as equipment failure, energy inefficiencies, or structural stress. This twin empowers teams to shift from reactive to proactive decision-making, reducing downtime and optimizing maintenance schedules.

Level 4: Comprehensive Twin

The Comprehensive Twin represents a fully integrated model capable of simulating future scenarios. It combines advanced modeling, historical data, and prescriptive analytics to recommend actions based on predicted outcomes. Whether evaluating renovation strategies or optimizing energy performance, this twin supports strategic planning with high-fidelity simulations and scenario testing.

Level 5: Autonomous Twin

At the highest level of maturity, the Autonomous Twin leverages artificial intelligence to learn, adapt, and make decisions independently. It uses advanced algorithms for simulation, 3D visualization, and operational control—enabling automation & automated responses to changing conditions. This twin is ideal for smart buildings and infrastructure systems that require continuous optimization without manual intervention.

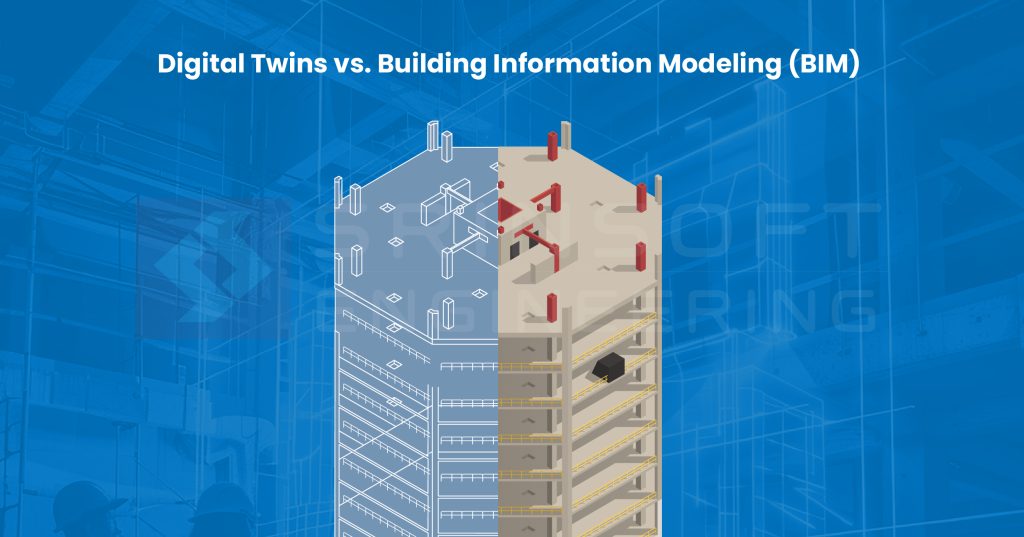

Digital Twins vs. Building Information Modeling (BIM)

While both Digital Twins and Building Information Modeling (BIM) are pivotal in the AEC industry’s digital evolution, they serve distinct purposes across the asset lifecycle. BIM is primarily focused on the design and construction phases, offering a static, data-rich 3D model that supports collaboration, visualization, and documentation. Digital Twins, on the other hand, extend beyond construction into operations, maintenance, and optimization. They integrate real-time data from sensors and systems to create a dynamic, living model of the physical asset. In essence, BIM helps build the asset; Digital Twins help run it

Benefits of Digital Twins in the AEC industry

1. Predictive Maintenance

Digital twins enable real-time monitoring of building systems, allowing facility managers to anticipate equipment failures before they occur. By analyzing sensor data and usage patterns, teams can schedule maintenance proactively, reducing downtime and extending asset life, especially critical for high-value infrastructure.

2. Enhanced Design Validation

By simulating real-world conditions within a digital environment, architects and engineers can validate design choices early in the project lifecycle. This includes testing energy performance, structural behavior, and user flow, leading to fewer design revisions and more informed decisions before construction begins.

3. Improved Construction Efficiency

During the build phase, digital twins help track progress, detect deviations from plans, and optimize sequencing. Real-time data from drones, sensors, and site equipment feeds into the twin, enabling faster issue resolution, reduced rework, and tighter coordination across teams and trades.

4. Lifecycle Optimization

Unlike BIM, which often ends at handover, digital twins continue to deliver value throughout the asset’s lifecycle. From operations to renovation and even demolition, they provide a living record of performance, usage, and upgrades, supporting smarter long-term planning and investment decisions for facility management.

5. Sustainability and Energy Management

Digital twins empower building owners to monitor energy consumption, carbon emissions, and environmental impact in real time. This data-driven insight supports compliance with green building standards and helps optimize HVAC, lighting, and water systems for maximum efficiency in sustainable construction

6. Enhanced Stakeholder Collaboration

With a centralized, dynamic model accessible to all stakeholders, digital twins foster transparency and alignment. Whether it’s architects, contractors, or facility managers, everyone works from the same source of truth, reducing miscommunication and accelerating decision-making.

7. Risk Mitigation and Safety

Digital twins can simulate emergency scenarios, monitor structural health, and track occupancy patterns to enhance safety protocols. By identifying vulnerabilities before they become hazards, they help reduce risk and improve compliance with safety regulations.

8. Cost Savings Over Time

While initial setup may require investment, digital twins drive long-term cost savings through reduced maintenance, fewer design errors, and optimized operations. The ability to simulate and test before acting minimizes waste and maximizes ROI across the asset lifecycle.

Conclusion

Digital twins are more than a buzzword, they’re a strategic enabler for smarter, safer, and more sustainable built environments. By bridging the gap between design and operations, they empower AEC professionals to make data-driven decisions that improve outcomes across the entire asset lifecycle. Whether you’re designing skyscrapers or managing campuses, embracing digital twins is a step toward future-proofing your projects.