Piping is an indispensable part of many vital industries where transport of fluids (liquids and gases) is an integral part of operations. Piping systems operate in the background, often without visible signs of complexity or importance. However, there is a symphony of disciplines of flow dynamics, material science, and structural planning behind a robust piping design.

Piping is often undervalued during early project phases or by decision-makers focused on “visible” assets like turbines, control systems, or reactors. When this seemingly minor aspect fails in its function, the consequences are dire. This understated importance makes it both fascinating and vital to get the piping systems right.

Key Concepts in Piping Design

Piping design is a multidimensional process that demands careful evaluation of several aspects. Here are some key concepts in the design of piping systems.

1. Design Objectives

Effective piping design is critical in industries like oil & gas, chemical, food processing, HVAC, and power plants to deliver the right amount of fluid, at the right pressure and temperature, when and where it’s needed.

A good piping design is rooted in a set of clear objectives:

- Ensure the uninterrupted and efficient flow of fluids

- Maintain safe operating conditions

- Allow for ease of inspection and maintenance

- Minimize both initial and long-term costs

Achieving these objectives helps optimize productivity and operational uptime, in addition to ensuring worker safety, protection of assets, lower maintenance costs and having better ROI.

2. Factors Influencing Design

The design of piping elements is predicated on several factors which affect everything from the materials used to the length and placement of pipes. Here are some of those critical factors that affect piping design.

3. Fluid Characteristics

The physical and chemical characteristics of the fluid decide what kind of materials need to be used and how the pipes should be laid out so that they’re transported safely and efficiently.

For example, aggressive chemicals may require corrosion-resistant alloys, while high-velocity steam demands routing that avoids excessive pressure drops and erosion.

4. Pressure Drops and Velocity Control

In any piping system, fluid dynamics play a central role, especially pressure drop and flow velocity, which directly affect how effectively and safely a system performs. If the design of the pipes doesn’t factor in for these parameters, the fluid moving through them can cause turbulence and even damage the surface of the pipes by causing cavitation.

5. Accessibility and Operability

In large industrial plants, like those in chemicals, oil & gas, or power plants, workers should be able to quickly reach valves or control panels. Delayed access to these devices, even by a few seconds, can result in major safety incidents.

It’s also important that these parts are easy to reach for maintenance teams. If they’re not, workers might have to take apart big sections of the piping system just to fix something small.

6. Safe Pipe Routing

Piping designers must also consider safety zones, especially when transporting flammable or toxic substances. Routing away from populated or sensitive areas and designing for containment and isolation becomes paramount.

7. Thermal Expansion and Vibration

Thermal expansion is a critical factor to be accounted for while designing piping systems. Although it is often overlooked, thermal expansion can wreak havoc if ignored. This is because, when metal pipes expand due to rise in temperature, they cause structural strain and when expansion becomes intense it can lead to failure of the piping system.

Additionally, vibrations are another important aspect of piping design. Vibrations influence pipe routing and design, especially near pumps and compressors, to prevent fatigue over time.

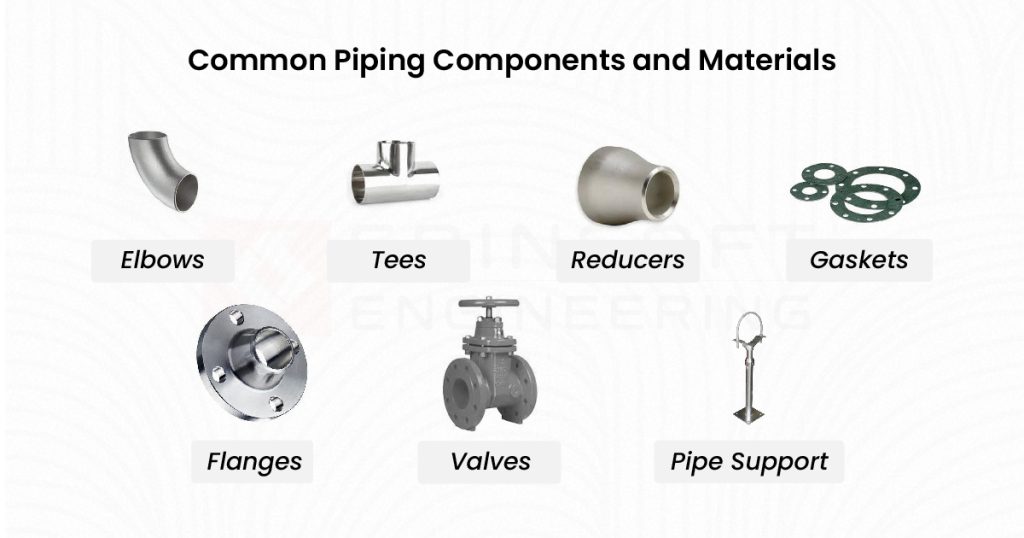

Common Piping Components and Materials

A well-functioning piping system is a synergetic structure made up of several components, each carrying a specific function that ultimately serves the purpose of moving fluids in controlled, directed, and safe manner.

Following are some of the key elements in a piping system:

- Elbows – These are used to change direction

- Tees – Components to split or combine flow

- Reducers – Used to connect pipes of different diameters

- Flanges and Gaskets – To create a secure, leak-proof connection between pipe joints

- Valves – These components regulate flow and pressure

- Pipe supports – Designed to support the weight of the pipes and the materials they carry, and to control their movement

The choice of materials is equally crucial when building a piping network. The selection of the material depends upon the operating environment and the nature of the fluid being carried.

Here are some of the common materials used in piping systems:

- Carbon steel – This is a common go-to for its strength and cost-effectiveness in non-corrosive conditions

- Stainless steel – Offers superior corrosion and temperature resistance, making it ideal for food, pharmaceutical, and chemical industries

- Copper and PVC (Polyvinyl Chloride) – These are typically used in HVAC (Heating, ventilation, and air conditioning) and plumbing due to their ease of installation and affordability

- HDPE (High Density Polyethylene) and Composite materials – These materials serve well in corrosive or underground applications

Materials are chosen based on unique properties (like strength, corrosion resistance, temperature tolerance, weight etc.) and the advantages that they offer. More often not, each material brings a trade-off between cost, longevity, and performance.

For example, Carbon steel is cheaper than stainless steel but corrodes faster while exotic alloys (like Inconel or Hastelloy) offer superior corrosion resistance but come at a premium cost.

Deciding the right material for the piping system impacts the reliability of the entire infrastructure and long-term success of the project.

Tools and Software Used in Piping Design

Undoubtedly, modern piping design has come a long way from paper drawings and manual calculations to digitizing the entire process to render more accurate and construction-ready designs from the start.

Here are some of the common and powerful software used in piping design:

✅ AutoCAD Plant 3D and PDMS –

These are widely used for 3D modeling and hassle-free layout planning.

✅ Revit and Navisworks –

These tools are known for their Building Information Modelling (BIM) capabilities. Revit is used for the initial design and modeling of piping systems within a building or structure, while Navisworks is used for clash detection, coordination, and project review.

✅ CAESAR II –

This is a go-to solution for stress and compliance analysis. The software has features to simulate loads, movements and thermal effects which are very useful capabilities to validate the integrity of a design.

✅ Solidworks –

SolidWorks is a 3D CAD software useful for creating 3D piping assemblies. Solidworks can automate routing of pipes and tubes using libraries of standard components and has real-time collision detection as well.

✅ SP3D –

SP3D is a comprehensive 3D modeling tool used in large-scale plant and infrastructure design. This is a preferred tool for detailed piping layout for complex industrial facilities.

✅ E3D –

E3D is a next-generation plant design solution having 3D modeling with cloud collaboration features. It also has advanced visualization and laser-scan model integration

Explore About: Mechanical Design Workflow Automation

Standards Used in Piping Engineering

In piping engineering, adhering to standards is a fundamental necessity to ensure system safety, reliability, and performance. Among the most referenced is ASME B31.3, which defines comprehensive standards for process piping systems.

The code mandates that design calculations take into account internal/external pressure handling, thermal expansion, seismic and environmental load considerations, and corrosion allowances.

For selecting the right material, ASMEB31.3 requires materials to meet specific criteria for strength, temperature resistance, and fluid compatibility.

B31.3 enforces rigorous inspection and testing, such as NDT methods and pressure tests to verify system integrity. It also regulates fabrication and installation, requiring qualified personnel and certified procedures for welding and jointing.

Other organizations, like ANSI, ASTM, API, and ISO, provide additional standards for materials, manufacturing tolerances, and testing methods. For instance, ASTM specifies the mechanical properties of metals, while API outlines practices for oil and gas facilities.

Challenges in Piping Design

Despite the availability of modern digital tools, designing piping systems isn’t devoid of impediments and challenges. Real-world scenarios are far from simplistic, requiring deep technical know-how and collaboration across disciplines to put together a robust piping network.

Here are some of the common challenges in piping design:

1. Space Constraints

Industrial sites are packed with infrastructure, electrical conduits, HVAC ducts, and other systems that need to co-exist with piping networks. This puts a constraint on how and where piping must be placed.

Piping systems must be designed so that they are maintainable and don’t interfere with other infrastructure.

2. Clash Detection

Since industrial environments are filled with various systems, it is extremely important during design to identify physical clashes between different systems. Failing to recognize interferences leads to expensive delays during construction and even safety risks.

Modern 3D modeling software (like Navisworks, Plant 3D, or PDMS) helps engineers detect these clashes virtually, so they can be resolved in design rather than onsite.

3. Thermal Expansion and Stress Management

Thermal expansion and contraction, particularly in high-temperature systems, can lead to pipe movement that stresses connections and supports. If not accounted for, this can shorten the life of the system or even cause failures.

Piping design should also ensure that there are expansion loops, anchors, or flexible joints to avoid fractures and misalignment due to stress.

4. Integration with Other Systems

Designers must also ensure alignment with multiple disciplines and stay responsive to frequent changes in scope or layout. Collaboration across disciplines is essential for a robust design.

Conclusion

Piping systems are the veins and arteries of industrial plants carrying vital fluids to keep the synergy of machinery and infrastructure running. Getting the piping design right is the stepping stone and yet one of the most critical aspects in the piping project.

At SrinSoft, we specialize in delivering highly efficient, accurate, and regulation-compliant piping design solutions, tailored to industry-specific needs. Our deep expertise in BIM-integrated piping design ensures seamless collaboration, clash-free layouts, and faster project turnaround whether it’s for oil & gas, manufacturing, energy, or heavy industrial facilities.